Many factors impact the performance of synthetic filtration media, from thread and weave styles to drainage and coverage considerations

Under the broad umbrella of filter media, there are many synthetic media materials, including woven filter cloths, woven and non-woven fabric filter media and filter felts. The term “synthetic” encompasses cloth materials made of polyethylene (PE), polypropylene (PP), polyester or nylon, as well as other specialty materials, such as Saran, polyamide, Nomex (flame-resistant meta-aramid), polyether ether ketone (PEEK), fluoroplastics and other specially made materials for specific applications. A sub-category of such media includes wire-cloth filter media. These are woven wire mesh made of a variety of metals, the most common being wire mesh made of stainless steels, such as 316 SS and 316-L SS.

Originally, the materials used for filter media were silk, cotton and wool. Due to the limitations on the usability of those materials, synthetic materials are used much more often in industrial filtration applications since their introduction around 1945. Since then, rapid development activities have widely expanded synthetic fibers’ applicability in industrial filtration. While cotton and wool are still used as filter media, this article covers synthetic filter media and wire cloth only.

Common fiber types

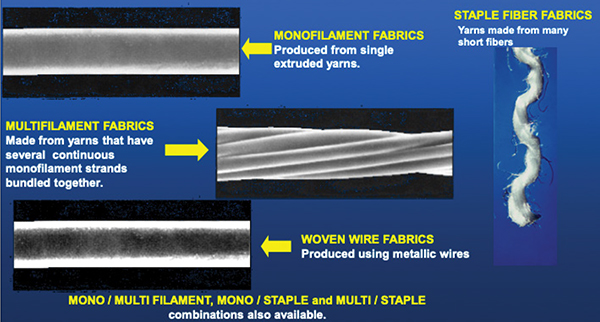

As shown in Figure 1, there are several common types of fibers used in synthetic filter media, as follows:

- Staple fiber fabrics — Yarns made of many short fibers

- Spun filament fibers — Yarn made from multiple discontinuous, small monofilaments twisted together

- Monofilament fabrics — Fibers produced from single extruded yarns

- Multifilament fabrics — Fabric made from yarns that have several continuous monofilament strands bundled together

- Woven wire fabrics — Media produced using metallic wires

FIGURE 1. The fiber type used for filtration media can impact its final performance

Also note that combination materials are available, such as mono/multifilament, mono/staple and multi/staple combinations.

Monofilament fibers offer many benefits, including excellent diameter control for precise fabric openings, high flowrates, low pressure drops, relatively high stiffness and tensile strength. With these fibers, the filtration mechanism is surface particle capture, exhibiting excellent surface particle release. This media is easy to clean, and also demonstrates limited liquid absorption.

With multifilament fibers, users should note that the twisted yarns can often result in uneven yarn diameters, and pore sizes can be uneven and difficult to measure. With this type of media, the filtration mechanisms include particle capture on the surface, as well as between twisted strands. Multifilament media elements exhibit fair surface particle release, but they are somewhat difficult to clean. Their benefits include excellent tensile strength, flexibility, pliability and fatigue resistance. It also should be noted that multifilament yarns can absorb liquids.

Spun filament fibers are characterized by a somewhat uneven fiber size and density, and like multifilament fibers, their pore sizes can be uneven and difficult to measure. The filtration mechanisms for spun filament fibrous media include particle capture on surface, as well as within the fiber structure. While these media are indeed flexible and pliable, they exhibit poor surface particle release, and are difficult to clean. As with multifilament fibers, spun filament yarns can absorb liquids.

Common weave styles

The method used to weave fibers into the larger filter-media elements can make a significant difference in performance parameters. Several weave styles are described in the following sections. The pore sizes available for the main weave categories are given in Table 1.

Square weaves. This weave style is mainly used with synthetic materials and wire cloth. It is the most basic open-weave style, employing a simple over-and-under pattern (Figures 2 and 3). It provides a straight flow path with a large open area. Some of the main benefits of square weaves are: high permeability, minimal binding, easy cleaning and high stability.

Taffeta weave. This weave style is typically used with synthetic materials only. It is a variation of square weaves where two small-diameter threads alternate with larger-diameter threads in the warp direction (Figure 4). “Warp” refers to the wires running the length of the cloth as it is woven. This style, with its rougher surface, mimics silk molting cloths.

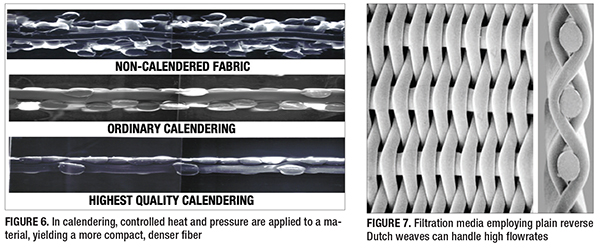

Closed twill weave. This weave style is used with synthetic materials. The denser weave pattern involves the warp threads going over three times, then under one weft thread (Figure 5). This weave style promotes excellent strength and durability. Filter media employing this weave style may be calendered to control air permeability. Calendering is a fiber treatment process whereby pressure and heat are applied at the same time to compress the fibers together, resulting in a thinner and tighter fabric with better filtration quality. As seen in Figure 6, calendering results in a more compact, denser fiber.

Twill Dutch weave. This weave style is used with wire cloth media. It provides the finest particle retention with its two-over, two-under pattern. In this style, the warp wires are heavier than the shute wires (the wires running across the width of the cloth).

Plain reverse Dutch weave. This weave style is used with both synthetics and wire cloth media. It has a higher warp thread count versus weft threads (Figure 7). The warp yarn diameter is generally two-thirds of the weft yarn diameter. This weave style can accommodate high flowrates, and it provides excellent longitudinal flexibility, transversal rigidity and tortuous flow.

Filtration media employing plain reverse Dutch weaves can handle high flowrates

Plain Dutch weave. This weave style is used with wire cloth media in high-flowrate applications. Its shute wires are smaller than its warp wires (Figure 8). A benefit of this weave style is a low pressure drop across the media.

Double-layer weaves. Double-layer weaves are used with synthetic media. These can be of the monofilament or mono-multi-weave variety. In double-layer weaves, the filter layer (for example, a closed twill-weave filter) and the support layer (for example, an open-square weave) are woven together. This configuration results in fine filtration capabilities, as well as exceptional strength and durability. There are various constructions available for double-layer woven media (Figure 9). Since fine fabric is woven onto a strong support layer, fabric pores tend to “blind-off” against a perforated metal support, as seen in Figure 10. In a monofilament configuration, lateral flow through the coarse mesh bottom layer results in improved flow and throughput (Figure 11).

Performance considerations

When selecting the proper filter media, the main performance issues taken into consideration are particle capture efficiency, throughput capacity, washability, cake release, temperature resistance and chemical resistance. Table 2 provides information on temperature and chemical resistance for several common synthetic materials.

Particle capture efficiency. It is important to note that 100% particle capture efficiency is often not necessary, as it may be too costly to be feasible in a particular project. Furthermore, fabric pore size does not necessarily have to exactly match the capture objective (as in cake filtration, for instance).

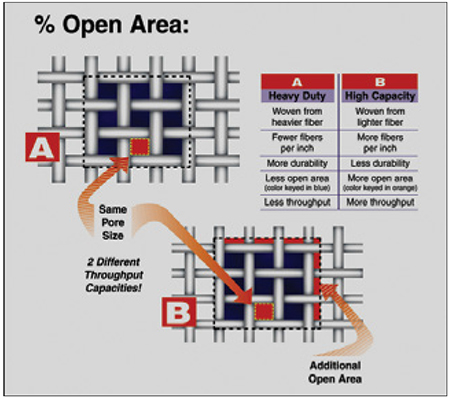

Throughput capacity.When considering throughput capacity, it should be understood that media with the same pore sizes can exhibit different throughputs, as shown in Figure 12. The open area of the media is what will ultimately set the capacity.

Washability and cake release. These considerations describe how well the cloth can be washed, and how well the filter cake releases when cleaning the filter cloth. Both of these factors help to predict the lifecycle effectiveness of the media.

FIGURE 12. Throughput capacity is not dictated by pore size, but rather the open area of the media

Drainage

This metal filter leaf is equipped with a honeycomb-style drainage support

Consideration must also be given to providing a drainage support between the filter media and the surface underneath. In the case of filter cloth media, it has been found in some cases that providing a drainage support consisting of a coarse, open media types may increase flow by as much as 20%. The drainage support is either an open-square weave made with coarse threads or filaments, or what is known as honeycomb. The drainage member separates the cloth from the metal support and thus creates more flow, since it allows for a lateral flow under the cloth. In the case of the woven wire mesh, the drainage member is usually a more open coarse-square mesh, such as 8 × 8 mesh. Figure 13 shows a metal filter leaf with the honeycomb support and the synthetic cloth cover open to show the support. Figure 14 shows a five-ply filter-leaf construction with drainage mesh.

Filter-cloth covers

While filter-cloth covers are sewn when originally installed onto the filter leaves, replacement filter-cloth covers may be supplied with either Velcro closures or zippers to facilitate field installation and eliminate the need to be sewn, which may require sending the filter leaves to a shop for sewing. Care must always be taken to prevent dragging filter leaves with cloth covers on them across the floor. This will tear or rip the cloth. Also, users must be careful not to hit the covered leaves against sharp surfaces that might damage the cloths. The cloths should be inspected periodically for any wear, tears or holes in the cloths. Such damage will most certainly affect the filter’s performance. A good preventative measure is to supply the cloth covers with reinforcement patches either on the corners, or any areas where the bags may be subject to friction or wear. ■

Edited by Mary Page Bailey

Acknowledgements

The author acknowledges the valuable contribution toward writing this article of Sefar Americas Inc. (Buffalo, N.Y.) and Filter-All, Inc./Sewn Weld Industries Inc. (Magnolia, Tex.)

Author

Jose M. Sentmanat is the president of Liquid Filtration Specialist, LLC (P.O. Box 1064, Conroe, TX 77305-1064; Website; www.filterconsultant.com; Email: [email protected]; Phone: 936-756-5362). Sentmanat has over 50 years of experience in application engineering, sizing and selection of filtration equipment for a multitude of process-related industries in the food-and-beverage, pharmaceutical, consumer, chemical and petrochemical sectors. Sentmanat has authored several publications, references and operations manuals, and has given numerous seminars and short courses worldwide.

Jose M. Sentmanat is the president of Liquid Filtration Specialist, LLC (P.O. Box 1064, Conroe, TX 77305-1064; Website; www.filterconsultant.com; Email: [email protected]; Phone: 936-756-5362). Sentmanat has over 50 years of experience in application engineering, sizing and selection of filtration equipment for a multitude of process-related industries in the food-and-beverage, pharmaceutical, consumer, chemical and petrochemical sectors. Sentmanat has authored several publications, references and operations manuals, and has given numerous seminars and short courses worldwide.